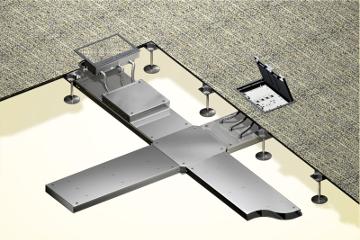

Immerse yourself in the world of efficient cable containment with Future Hajar's Cable Trunking & Fittings. Engineered with precision, our trunking solutions offer a straightforward approach to managing lightweight and structured cables. Designed to meet the exacting standards of BS 4678 & BS 50085, our range includes single or multi-compartment surface trunking options.

Both the trunking body and sections are conveniently supplied in 3-meter lengths, complete with couplers and all essential fixing components. Our weldless joints and robust fixing arrangement ensure unmatched durability. This system not only guarantees earth continuity between the body and lid but also accommodates variations in sheet thickness while maintaining secure lid-body integration.

Complement your setup with a diverse selection of fittings and accessories meticulously crafted to augment and complete the range.

Materials & Finishes

Pre-Galvanized zinc-coated steel, equivalent to JIS G3302 and BS EN 10142 (superseding BS2989), meeting ASTM A653 standards. For added protection, opt for Pre-Galvanized zinc-coated steel, equivalent to JIS G3302 and BS EN 10142 (superseding BS2989), ASTM A653, with a 60-micron minimum film thickness of Epoxy Powder Coating post-fabrication.

Choose durability through hot-dip galvanization, utilizing Hot Rolled Steel to BS 10149-3:1996 and Cold Rolled Steel to BSEN 10130:2006, followed by post-galvanization as per BS EN 1461 (Formerly BS729) and ASTM-A123.

Elevate your setup with Stainless Steel Sheet conforming to ASTM A240 type 304 and 316L specifications. Additionally, Aluminum Grade AA1100 offers lightweight alternatives for your cable management needs.

Elevate Connectivity: Future Hajar's Cable Trunking & Fittings – Where Functionality Meets Aesthetic Precision