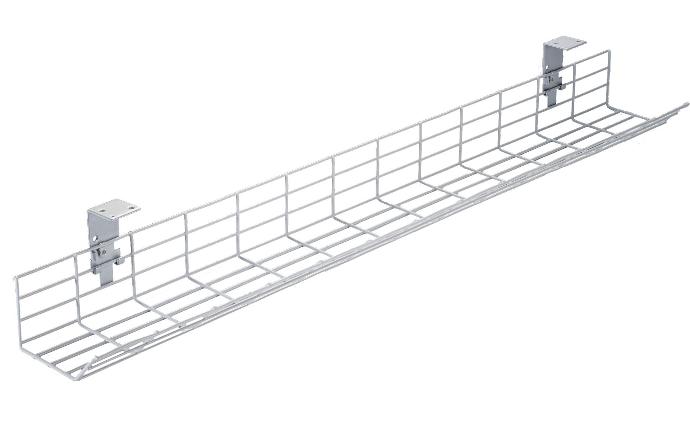

Future Hajar stands as an industry leader, setting the pinnacle of excellence with its Cable Ladder & Fittings that redefine the landscape of cable management solutions. Meticulously engineered with an unwavering commitment to precision and durability, our cable ladder systems transcend conventional approaches, ushering in a new era of efficiency in cable organization. At the heart of our offerings lie robust cable ladders, meticulously designed to bear supreme loading capacities. Complemented by an array of fittings that seamlessly facilitate customization, each component serves as a testament to our dedication to unparalleled quality.

The versatility of our Cable Ladder system is highlighted by its standard widths, ranging from 100mm to 1000mm, with the flexibility to cater to custom widths upon request. Crafted from top-tier steel, our ladders incorporate Hot Rolled Steel to BS EN 10149-3:1996 and Cold Rolled Steel to BS EN 10130:2006, followed by Post Galvanization to BS EN 1461 (formerly BS 729) and ASTM-A123. This meticulous process ensures the creation of a robust, corrosion-resistant solution that excels in cable loading capacity and durability across diverse industrial applications.

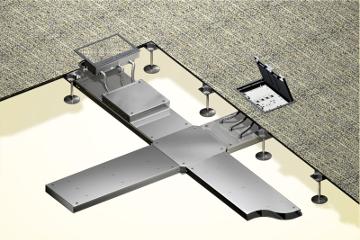

Adding to our innovative offerings, we introduce the novel Marine Profile & C Profile cable ladder system, a hallmark of lightweight design, space optimization, and cost-effectiveness.

Our commitment to providing versatile solutions is extended to various metals, including Stainless Steel Grades 304 or 316L, as well as Aluminum, available in an array of finishes like Epoxy Powder Coating and Wet Paint.

Intricately designed, our standard fittings boast a 300mm radius, while provisions for accommodating other radii exist upon request. Rung centers, set at 300mm as the default, cater to different rung center preferences, ensuring adaptability to distinct needs.

Completing the comprehensive offering, a diverse selection of Fittings and Accessories seamlessly integrate with the entire range, enhancing its functionality and utility.

Materials & Finishes

Opt for Hot-dip galvanization utilizing Hot Rolled Steel to BS 10149-3:1996, Cold Rolled Steel to BSEN 10130:2006, followed by post-galvanization per BS EN 1461 (Formerly BS 729) ASTM-A123.

Alternatively, choose the Hot-dip galvanization approach that employs Hot Rolled Steel to BS 10149-3:1996, Cold Rolled Steel to BS EN 10130:2006, succeeded by post-galvanization as per BSEN 1461 (Formerly BS 729) ASTM A123, offering the flexibility of Epoxy Powder Coating or a 3 Coat Wet Paint System.

Elevate your solution with Stainless Steel Sheet adhering to stringent ASTM A240 type 304 and 316L specifications. Our offerings extend to Aluminum of Grade AA1100, meeting the requirements of diverse applications and industries

Elevating Connectivity: Future Hajar's Cable Ladder & Fittings – Where Strength Meets Adaptability.